(Executive order no. 1114 from August 18th, 2016)

In pursuance of Section 5(1)(i), Section 5(2), Section 7(3), Section 31(1)-(2), Section 34(2) and Section 39 of the Danish Act No. 525 of 29 April 2015 on the Safety of Electrical Plants, Electrical Installations and Electrical Equipment (the Electrical Safety Act), the following is laid down:

Executive Order: Construction of plant

Part 1:Scope and definitions

Scope

1(1). This Executive Order applies to the construction of electrical plants and primary high-voltage installations, cf. however subsections (2)-(3) below.

(2). The Executive Order does not apply to the construction of electricity-producing plants constructed according to the Executive Order on Safety in connection with the Construction and Operation of Electrical Installations.

(3). The Executive Order does not apply to the construction of storages for electrical energy constructed according to the Executive Order on Safety in connection with the Construction and Operation of Electrical Installations.

Definitions

2. The following definitions are used in this Executive Order:

i) Protection against direct contact: Measures that prevent people from coming dangerously close to live parts or the parts that may have a dangerous voltage, with body parts or objects.

ii) Protection against indirect contact: Protection of people against the dangers that may occur in case of faults from contact with exposed live parts of electrical equipment or extraneous conductive parts.

iii) Danger zone: The live working zone DL. Area surrounding live parts where the insulation level for protection against electrical danger is insufficient when persons reach into or enter the area, cf. EN 50110, Annex A.

iv) Fault protection: Protection against electric shock under single-fault conditions.

v) Basic protection: Protection against electric shock under fault-free conditions.

vi) High-voltage plants: Electrical plants with a nominal voltage in excess of 1000V a.c. or 1500V d.c.

vii) Low-voltage plants: Electrical plants with a nominal voltage up to and including 1000V a.c. or 1500V d.c.

viii) Wiring: Overhead wires and cables forming part of an electrical plant.

ix) Closed electrical operating area: Access controlled room or area where electrical plants and equipment are operated.

x) Piping: All electrically conductive parts that are included in a metal piping system and the electrically conductive parts that are in contact with the piping system.

Part 2: Application and standards

Construction of electrical plants in excess of 1000V a.c. or 1500V d.c.

3. If an electrical plant in excess of 1000V a.c. is constructed in accordance with EN 61936-1 with any national conditions applicable to Denmark, the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-20 and Sections 26-36 of this Executive Order, shall be deemed to be met.

4. If an earthing system for electrical plants in excess of 1000V a.c. is constructed in accordance with EN 50522 with any national conditions applicable to Denmark, the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-20 and Sections 26-36 of this Executive Order, shall be deemed to be met.

5. If overhead wiring in excess of 1000V a.c. is constructed in accordance with EN 50341 with any national conditions applicable to Denmark, the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-20 and Sections 26-36 of this Executive Order, shall be deemed to be met.

6. If an electrical plant in excess of 1500V d.c. is constructed in accordance with standards published by the European Committee for Electrotechnical Standardization (CENELEC) with any special national conditions applicable to Denmark, the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-20 and Sections 26-36 of this Executive Order, shall be deemed to be met.

7(1). If an electrical plant is constructed close to metallic piping in accordance with EN 50443 with any national conditions applicable to Denmark, the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-20 and Sections 26-36 of this Executive Order, shall be deemed to be met.

(2). The safety requirement shall also be deemed to be met if the proximity of the electrical plant to metal piping is constructed in accordance with Appendix 1 to this Executive Order.

8(1). If an electrical plant is not or is only partially constructed in accordance with the standards mentioned in Sections 3-7 above, it must be documented that the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-20 and Sections 26-36 of this Executive Order, is met.

(2). The time of construction of the electrical plant determines what version of the standard series, cf. Sections 3-7 above, is applicable. In case the time of construction of the electrical plant is less than three (3) years after the design was completed, the standard series, cf. Sections 3-7 above, applicable in Denmark at the time the design was completed may be used.

Construction of electric railway systems

9(1). If an electricity supply to a railway system is constructed in accordance with standards published by the European Committee for Electrotechnical Standardization (CENELEC) with any special national conditions applicable to Denmark, the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-20 of this Executive Order, and the general safety requirements for the voltage level, cf. Sections 21-25 and Sections 26-36 of this Executive Order, shall be deemed to be met.

(2). If the electricity supply to a railway system is not or is only partially constructed in accordance with the standards mentioned in subsection (1) above, it must be documented that the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-20 of this Executive Order, and the general safety requirements for the voltage level, cf. Sections 21-25 and Sections 26-36 of this Executive Order, are met.

(3). The time of construction of the electricity supply to a railway system determines what versions of the standards, cf. subsection (1) above, are applicable. In case the time of construction of the electricity supply to a railway system is less than three (3) years after the design was completed, the standard versions, cf. subsection (1) above, applicable in Denmark at the time the design was completed may be used.

10(1). Where a railway system is constructed in accordance with standards published by the European Committee for Electrotechnical Standardization (CENELEC) with any special national conditions applicable to Denmark, the safety requirement in Section 3 of the Electrical Safety Act shall be deemed to be met.

(2). Where a railway system is not or is only partially constructed in accordance with the standards mentioned in subsection (1) above, it must be documented that the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-20 of this Executive Order, and the general safety requirements for the voltage level, cf. Sections 21-25 and Sections 26-36 of this Executive Order, are met.

(3). The time of construction of the railway system determines what versions of the standards, cf. subsection (1) above, are applicable. In case the time of construction of the railway system is less than three (3) years after the design was completed, the standard versions, cf. subsection (1) above, applicable in Denmark at the time the design was completed may be used.

Construction of electrical plants up to and including 1000V a.c. or 1500V d.c.

11(1). Where an electrical plant up to and including 1000V a.c. or 1500V d.c. is constructed according to the version of the standard series for low-voltage electrical installations applicable in Denmark, HD 60364, the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-25 of this Executive Order, shall be deemed to be met.

(2). Where an electrical plant is not or is only partially constructed according to the version of the standard series for electrical installations applicable in Denmark, HD 60364, it must be documented that the safety requirement in Section 3 of the Electrical Safety Act, cf. Sections 15-25 of this Executive Order, is met.

(3). The time of construction of the electrical plant determines what version of the standard series, cf. subsection (1) above, is applicable. In case the time of construction of the electrical plant is less than three (3) years after the design was completed, the standard series, cf. subsection (1) above, applicable in Denmark at the time the design was completed may be used.

12. Batteries used in commercial energy storages must be suitable and intended for the purpose and in accordance with the standards published by the European Committee for Electrotechnical Standardization (CENELEC) with any special national conditions applicable to Denmark.

Publication of standards

13. The standards to which this Executive Order refers are not published in Lovtidende (the official Danish Law Gazette), but may be purchased from Danish Standards or reviewed at the Danish Safety Technology Authority.

Part 3:General safety requirements

14. Sections 15-36 elaborate the safety requirement in Section 3 of the Electrical Safety Act.

15. An electrical plant must be constructed in such a way that it does not cause danger due to excessive temperatures, arcs or mechanical impact during normal operation, special operating conditions, short circuit or expected climatic conditions.

16. Overvoltages may not cause danger to persons, domestic animals or property.

17. An electrical plant must have immunity to electromagnetic disturbances so that it is able to function correctly in the relevant environment.

18. Electrical equipment included in an electrical plant must be installed and used in accordance with the instructions of the manufacturer.

19. An earthing system must be constructed in such a way that it functions under all conditions and provides safety for persons at any place to which they have legitimate access. In addition, it must be ensured that the electrical equipment for the earthing system remains intact and fault free.

20(1). Electrical plants and other objects may not be placed in such close proximity that danger can occur.

(2). When placing other objects in vicinity to existing electrical plants, any distance requirements to the electrical plant must be observed.

(3). The electrical plant or object established last shall be placed taking into account of the already placed plant or object.

Safety requirements for plants up to and including 1000V a.c. or 1500Vd.c.

21. An electrical plant must have basic protection so as to protect persons and domestic animals against the dangers that may arise from contact with the live parts of the plant.

22. An electrical plant must have fault protection so as to protect persons and domestic animals against the dangers that may arise from contact with the exposed conductive parts of the plant during a fault condition.

23. An electrical plant must be protected against overcurrent so that persons, domestic animals and property are protected against the dangers that may arise due to excessive temperatures or electromechanical influences caused by overcurrent.

24. For an electrical plant, protective conductors and any other part intended to carry a fault current must be able to carry such current without reaching excessive temperatures.

25. Faults between conductive parts in circuits to which various voltages are supplied may not cause danger to persons, domestic animals or property.

Safety requirements for plants in excess of 1000V a.c. or 1500V d.c.

26. An electrical plant must be protected against direct contact in such a way that contact with live parts or unintended entry into the danger zone surrounding live parts is avoided.

27. An electrical plant must be equipped with measures to protect persons against indirect contact in areas to which they have legitimate access.

28. An electrical plant must be protected with equipment for automatic disconnection of dangerous earth faults or for displaying earth faults.

29. An electrical plant must be constructed in such a way that it is able to resist normally occurring voltages, including overvoltages.

30. Where practical, an electrical plant must be constructed in such a way that undervoltage, earth faults or voltage failure of one or more live conductors will not lead to danger to persons, domestic animals or property.

31. An electrical plant must have the necessary monitoring, protective, control and inspection equipment so as to ensure that it works safely and as intended.

32. An electrical plant must be constructed taking into account the risk of dangerous induced touch voltages in other non-electrical plants in proximity to the electrical plant. If necessary, measures must be taken to minimise induced touch voltage to a level that is harmless for persons and domestic animals.

33. An electrical plant must be constructed in such a way, that work in connection with operation and maintenance of the plant may be carried out safely.

34(1). An electrical plant must have warning signs, marking and identification so as to avoid operating errors and accidents.

(2). Warning signs must be in compliance with the Executive Order on Safety Signs and Other Forms of Signalling.

35(1). All sides of the exterior fence surrounding an outdoor electrical plant and access doors to the plant must be provided with warning signs.

(2). Warning signs must be in compliance with the Executive Order on Safety Signs and Other Forms of Signalling.

36(1). All access doors to closed electrical operating areas must be provided with warning signs.

(2). Inside closed electrical operating areas and in industrial buildings, all rooms with electrical equipment must be marked with information that identifies the room and calls attention to possible electrical dangers. This information must be available outside the room and on every access door to the room.

(3). Warning signs must be in compliance with the Executive Order on Safety Signs and Other Forms of Signalling.

Part 4: Special safety requirements

Structures

37. Bearing structures must be dimensioned in accordance with Eurocodes with the associated Danish annexes.

38. In connection with static calculations of electrical equipment, supporting structures and foundations, wind and ice loads must be taken into account in accordance with the standards published by the European Committee for Electrotechnical Standardization (CENELEC) with any special national conditions applicable to Denmark.

Cables and conductors

39. When routing cables in buildings outside station rooms, it must be ensured that cables are sufficiently fireproof.

40(1). Where cables cross or are placed in proximity to other cables, the mutual thermal influences must be calculated in order to determine the minimum distance between the cables. If the calculated minimum distance cannot be observed, it must otherwise be ensured that there are no mutual detrimental influences between the cables.

(2). Cables must be installed at a sufficient distance from heat sources or be separated from heat sources by means of thermal insulation screens.

41. Cables must be buried at a minimum depth of 0.7m and be protected by conduits, U-profiles or cover plates.

42(1). Cover plates, conduits and U-profiles made from plastic material for protection of buried cables must be red.

(2). Cover plates must have a width of minimum 100mm and have the following warning text: ELKABEL.

(3). The warning text, cf. subsection (2) above, must

i. have a letter height of minimum 10mm;

ii. the letter colouring must be black and

iii. the text must be repeated at intervals not exceeding 200mm between prints.

(4). Subsection (3)(ii) only applies to cover plates if they are marked by stamping.

43. Where conductors and accessories are directly connected to a circuit breaker, a safety load break switch or a load break switch, the value and the duration of the nominal short-term withstand current for conductors and accessories must not be lower than the corresponding nominal value for the electrical equipment to which it is connected.

Operating aisles

44(1). Operating aisles must have a number of exits that provides sufficient escape possibilities in case of an emergency.

(2). Operating aisles longer than 10m must have minimum two (2) emergency exits.

Monitoring and control systems

45. The monitoring and control system of an electrical plant must be designed in such a way that it indicates the position of the switch and any given fault condition.

46. Motor-operated disconnectors, earthing switches, circuit-breakers and load break switches must be equipped with local operation for connection and disconnection.

Part 5: Existing plants

47(1). An electrical plant must be constructed in accordance with the rules applicable at the time of construction.

(2). In case of minor alterations to existing overhead wiring, the provisions applicable at the time of construction may be applied.

Part 6: Commissioning and reporting

48. Before a new electrical plant is commissioned, the person commissioning the plant must ensure that an operating company is in charge of the operation of the plant where the Executive Order on Safety of the Operation of Electrical Plants requires an operating company.

49(1). If the standard version applicable to the type of plant in question is not used or is only partially used, cf. Section 8(1), Section 9(2), Section 10(2) and Section 11(2), the company constructing the plant must report this via the electronic reporting system of the Danish Safety Technology Authority. Reporting is required for the following:

i. Expansion of an existing electrical plant.

ii. A new electrical plant.

(2). The documentation pursuant to subsection (1) above must include the following information and documentation:

i. The address of the electrical plant and any other information, so that the plant is clearly identified.

ii. The time the work was carried out.

iii. The time the design was completed if this is substantially different from the time of construction.

iv. Documentation of compliance with the safety requirements, cf. Section 8(1), Section 9(2), Section 10(2)or Section 11(2).

v. Documentation of the control that the electrical plant is in compliance with the technical documentation.

vi. Documentation of materials selection and choice of protective equipment.

vii. Calculations and assessments that form the basis for compliance with the safety requirements.

viii. Drawings and diagrams of the electrical plant.

ix. Unambiguously identifiable documentation of the part of the electrical plant on which work was performed.

(3). Reporting according to subsection (1) above must be carried out not later than 14 days after completion of the work.

Part 7: Penalty

50(1). Unless a higher penalty is incurred in pursuance of other legislation, anyone who

i. fails to observe Sections 15-46 and 48;

ii. fails to report, cf. Section 49(1);

iii. fails to report information pursuant to Section 49(2) or reports false information or

iv. fails to observe Section 49(3) above

shall be liable to a fine.

(2). Companies etc. (legal persons) may incur criminal liability in pursuance of the rules of Part 5 of the Criminal Code.

51. The period of limitation of the criminal liability is 10 years.

Part 8: Entry into force and interim provisions

52(1). This Executive Order comes into force on 1 July 2017.

(2). The following executive orders shall be repealed at 1 January 2019:

i. Executive Order of 1 January 1990 on the Heavy Current Rules, part A, section 4, earth connections etc. in and at station plants and wiring 3rd edition.

ii. Executive Order of 1 May 1994 on the Heavy Current Regulation, construction of electricity supply plants.

iii. Executive Order of 16 June 2005 on the Heavy Current Regulation, section 2, 2nd edition, construction of electricity supply plants.

iv. Executive Order of 1 October 2001 on the Heavy Current Regulation, section 9, 4th edition, High-voltage installations.

53(1). Electrical plants may be constructed according to sections 2, 6 and 9 of the Heavy Current Regulation until and including 31 December 2018.

(2). Electrical plants whose design is completed or commenced before 1 January 2019 according to section 2, 6 and 9 of the Heavy Current Regulation may be constructed or completed according to these rules until and including 31 December 2019.

(3). The Danish Safety Technology Authority may in special cases grant an exemption for completion of electrical plants whose design is completed or commenced before 1 January 2020 according to section 2, 6 and 9 of the Heavy Current Regulation after 31 December 2019. An application for such exemption must be received by the Danish Safety Technology Authority before 31 December 2019.

Appendix 1

Proximity between high-voltage plants and metal piping

High-voltage plants in the proximity of metal pipelines surrounded by an insulating coating or otherwise insulated to earth may under certain circumstances give rise to such electrical influences that it is dangerous to touch the piping and other electrically conductive parts in contact with the piping.

I – Electrostatically influenced plants

In case of electrostatic influence from a high-voltage overhead wire to a pipeline placed insulated to earth, the current from the piping to earth through a negligible impedance may not exceed 5mA. -

For a.c. high-voltage overhead wires, this provision may be deemed to be met when one of the following conditions is met:

-

1) The horizontal distance between the pipeline and the high-voltage overhead wire is minimum 50 metres and the length of the pipeline does not exceed 500 metres.

-

2) The length of the pipeline within the distance mentioned in 1) above does not exceed 150 metres.

-

3) The operating voltage of the high-voltage overhead wire does not exceed 60kV.

If there is a risk that the current will exceed 5mA, earth electrodes must be connected to the pipeline. Minimum one (1) electrode must be established for every 500 metres of pipe length.

II – Touch voltage, UTp

The voltage a high-voltage wire can induce on a proximate insulated pipeline is defined below as the voltage difference UTp between:

-

1) Parts of the piping that are accessible for touch at the same time.

-

2) Parts of the piping and earth accessible for touch.

-

3) Parts of the piping accessible for touch and other electrically conductive parts with connection to earth

that are accessible for touch at the same time.

-

4) Parts of the piping that are accessible to touch and circuits belonging to high-voltage and low-voltage

installations connected to neutral earth and located less than 1 metre from the piping.

III – Electromagnetic induction under normal operation of high-voltage plants

The induced voltage UTp on a proximate insulated pipeline may not exceed 50V under normal operation.

For three-phase high-voltage wires this requirement may be deemed to be met when one (1) of the following conditions is met:

-

1) The operating voltage of the high-voltage wire does not exceed 40kV.

-

2) The horizontal distance between high-voltage wire and pipeline is minimum 200 metres.

IV – Electromagnetic induction in case of faults on high-voltage plants

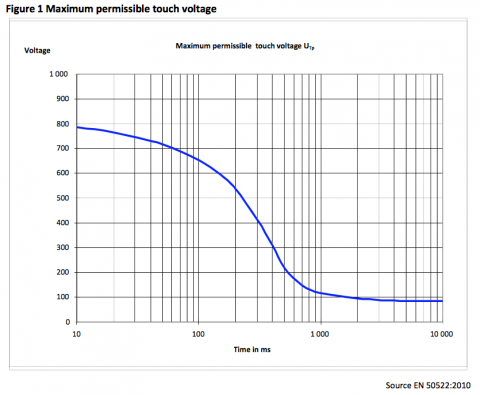

The induced voltage UTp on a proximate insulated pipeline may not exceed the value in Figure 1 in case of faults on the high-voltage plant.

If the disconnection time exceeds 10 seconds, UTp may not exceed 50V.

For three-phase high-voltage wires this requirement may be deemed to be met when the horizontal distance

between the high-voltage wire and the pipeline is minimum 1000 metres.

In networks where single earth faults are disconnected within 5 seconds or where the network is resonant earthed, double earth faults need not be considered.

V – Influences in case of increased earth potential

9

APPENDIX 1

In case of earth faults on a high-voltage overhead wire or in a high-voltage station, the increased earth potential surrounding the earthed pylon of the wire or surrounding the high-voltage station must not cause a higher voltage difference between parts of proximate insulated piping accessible for touch and earth than stated in Figure 1.

If the disconnection time exceeds 10 seconds, UTp may not exceed 50V.

For three-phase high-voltage plants this requirement may be deemed to be met when one (1) of the following conditions is met:

-

1) The operating voltage of the high-voltage plant does not exceed 60kV.

-

2) The distance from piping to the exterior limit of the high-voltage station is minimum 50 metres and the

distance from the piping to the earthed pylon of the high-voltage overhead wire is minimum 15 metres.

VI – Measures to protect against touch danger

The maximum voltage differences fixed in items III, IV and V may be exceeded if measures are taken to eliminate or limit the effects of the voltage differences to an extent that does not exceed the impact of the permissible voltage differences, cf. Figure 1.